DEC is based on the latest advances in material engineering to provide toolmakers with very high wear resistance material and an excellent Performance / Price.

Thanks to the enrichment of tungsten carbide with diamond, DEC material Exceed the Lifetime of conventional cemented carbide tools many times, giving way only to PCD tools but offering Competetive Price in return.

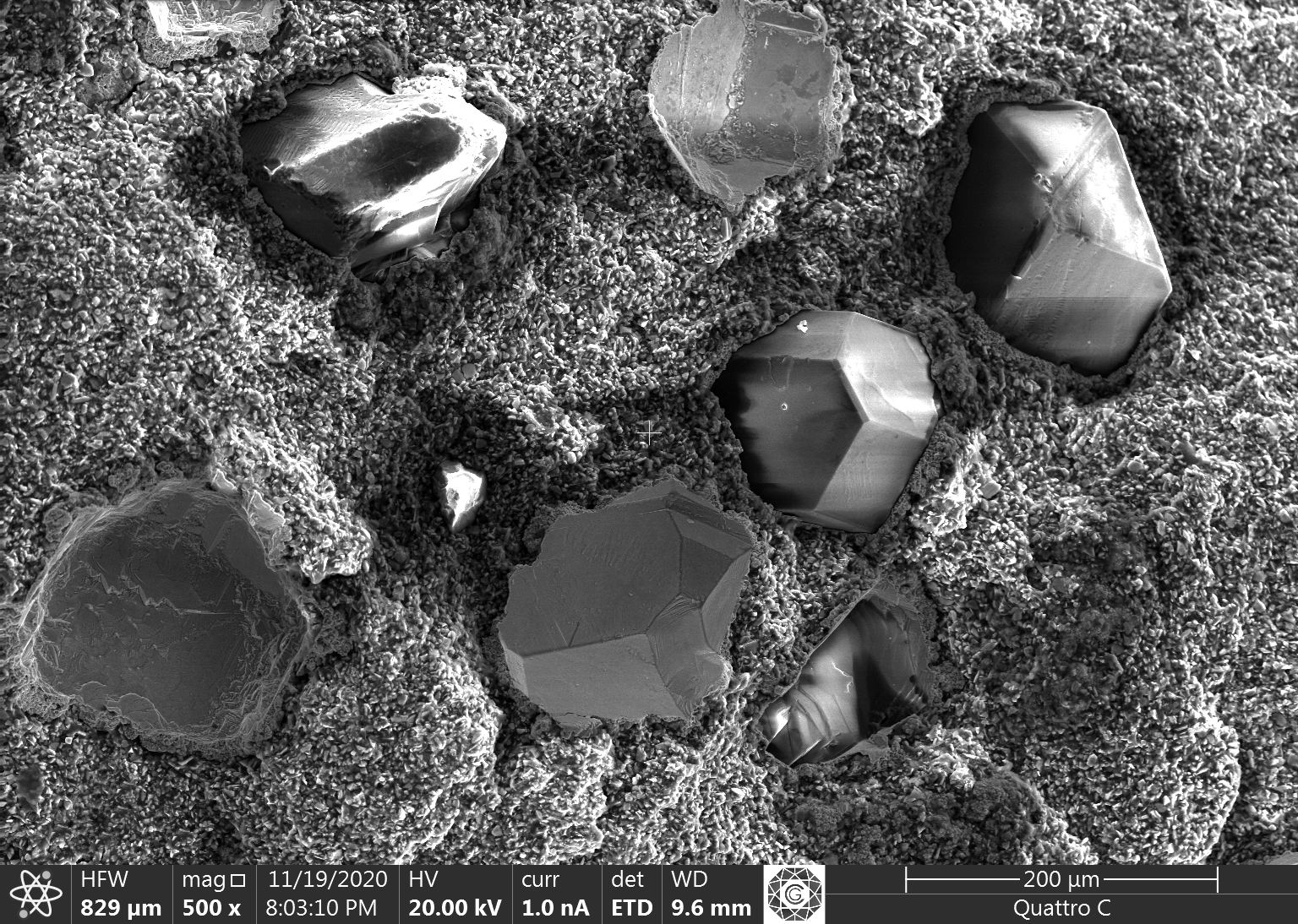

DEC is an innovative tool material, merging the best properties of diamond and cemented carbide. Our unique PPC (Pulse Plasma Compaction) technology enables the production of this composite material under the thermodynamic instability of diamond. This process enhances the durability and performance of tools, making them suitable for various demanding applications.

Proprietary Manufacturing Technology

The DEC material is crafted using our proprietary PPC technology, which ensures the integration of diamond particles into a cemented carbide matrix. This method enhances the hardness and resistance to abrasive wear, providing tools that last significantly longer than conventional tungsten carbide tools.

Physical Properties

High Hardness: The DEC composite boasts a superior hardness due to the diamond particles, significantly enhancing cutting performance.

Wear Resistance: The cemented carbide matrix improves resistance to abrasive wear.

Toughness: The combination of materials ensures both high impact resistance and toughness.

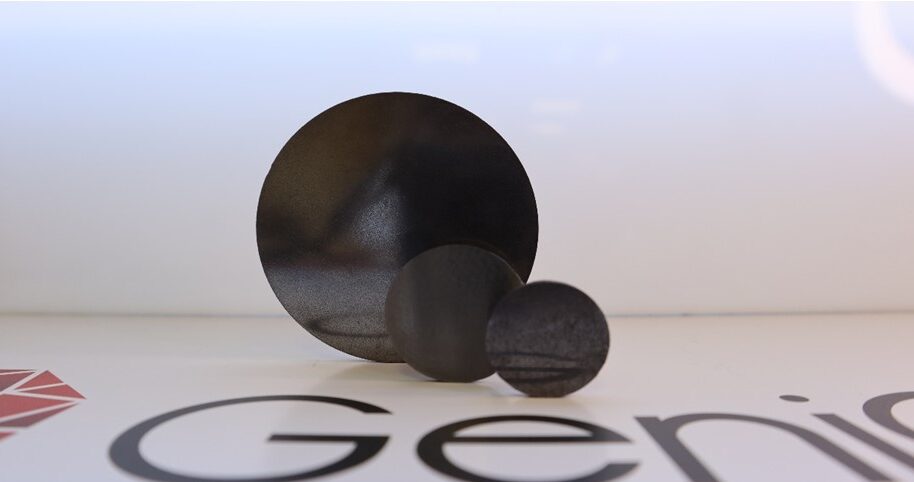

Example Roughness parameters reached for the DEC with a diameter 56.5mm (2”).

| Roughness [Ra] | Process |

| 0.438 μm | Sandblasting |

| 0.127 μm | Lapping |

| 0.0267 μm | Polishing |

Testing

Our tools undergo rigorous testing to ensure they meet the highest standards:

- Abrasion Resistance Tests: Evaluating the wear rate under high-stress conditions

- Impact Resistance Tests: Assessing the tool’s durability against sudden shocks

- Field Tests: Real-world applications to verify performance in various industries

GENICORE ASSURES

• DEC material continuous production method

additionally increasing performance/price ratio.

• Near net shape sintering

limiting necessary machining.

• Functionally-graded materials

designed for special applications.

Conclusion

Due to the wide range of possibilities for shaping DEC microstructure and thus its properties, the advantages of DEC have already been proven in many applications, including; Woodworking, Mining, Ceramic Processing or Road Surface Milling.

Contact Us

If you suspect that our material can be used in a different application, please contact us, and we will be happy to test it together. Delivery condition depending on the type of surface processing. Available at hand. Contact us to place an order. Just like DEC, we do not break easily even under extremely harsh conditions.