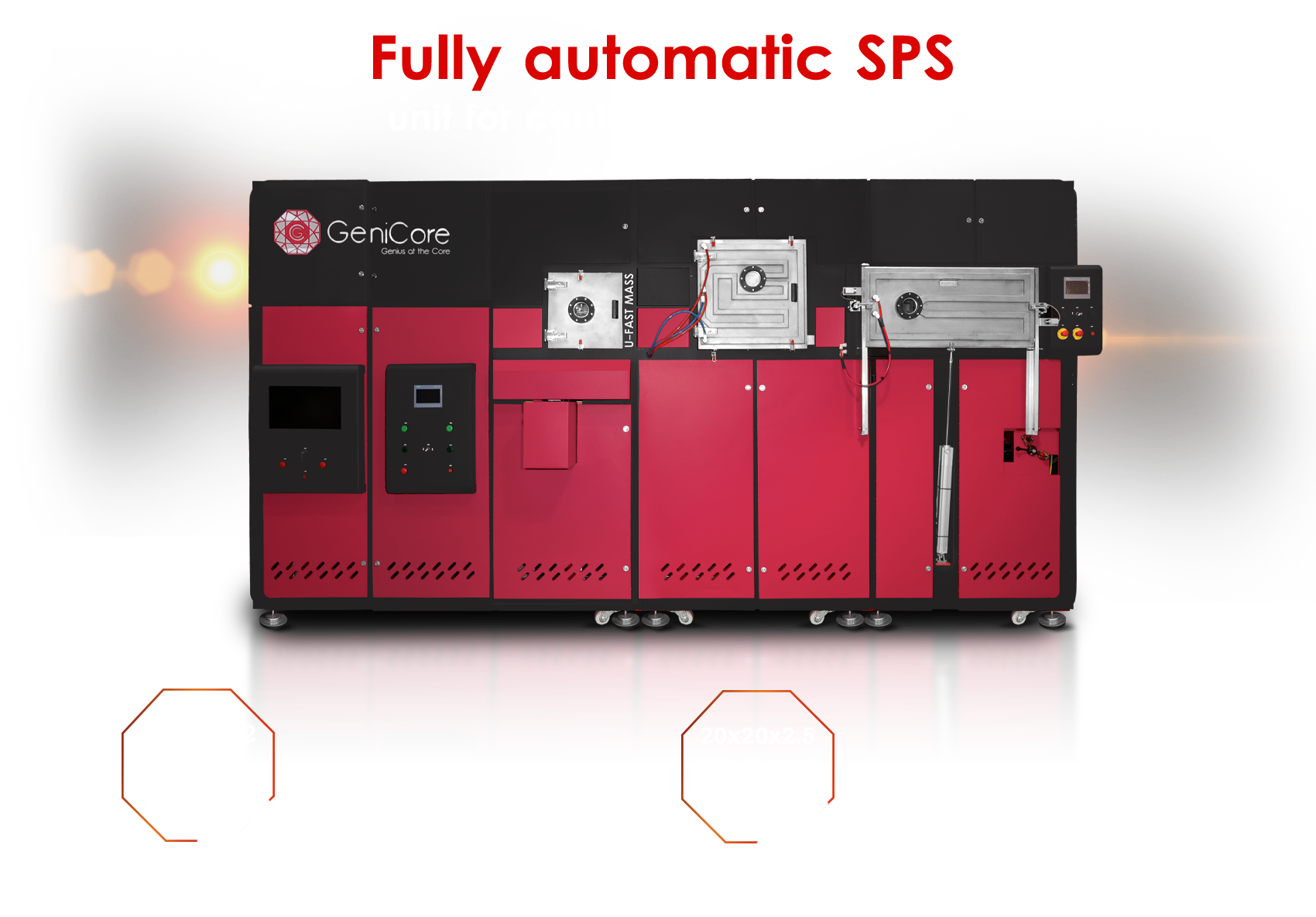

Technology inside U-FAST MASS

U-FAST MASS is our offer in the field of fully-automatic continuous sintering machines. Our systems, renowned as a spark plasma sintering machine for large-scale production, utilizes a highly sophisticated sintering processes. It employs very narrow electric pulses and mechanical pressure to efficiently convert powders into solid materials, showcasing the pinnacle of sintering technology. Central to U-FAST MASS is our innovative fast sintering U-FAST pulsed power system. We implement it with a great success in every all GeniCore machines. It enhances the capabilities of this sintering machine and significantly reduces its size and operational costs. MASS continuous sintering machine is designed to work under great pressure in environment where every delay means lost profit. System design allows precise customization of processing parameters, crucial in adapting to various materials, different geometries and production requirements.

*The automatic feeding system adjusted according to the sintered elements Size and frequency Of loading and peripheral Chambers.

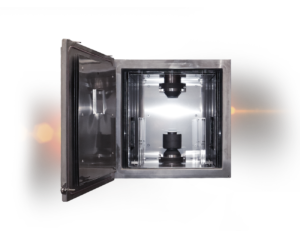

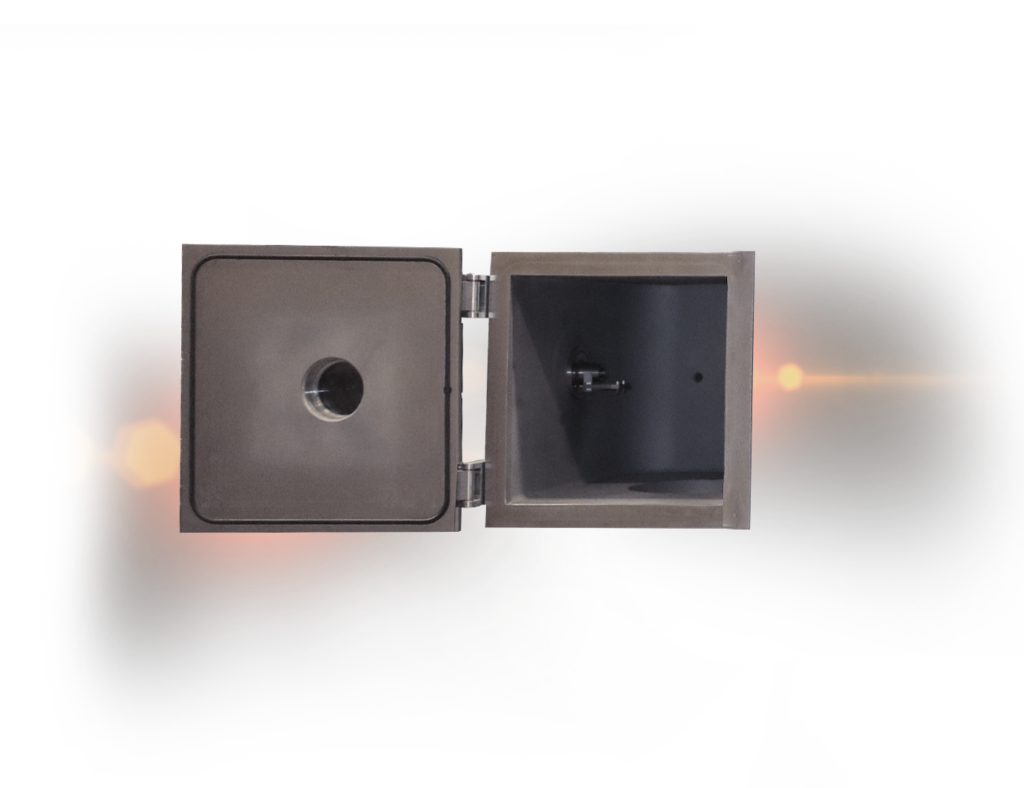

High-Speed Vacuum

Our world class vacuum-system and 3 chamber design allows us to achieve operational vacuum after just 60 seconds. It establishes unprecedented standards within the industry. Furthermore, the systems within U-FAST MASS are meticulously engineered to function in unison, delivering unmatched efficiency. Look at estimated annual production.

Autonomous Sintering Process

The automated feeding system, pivotal in continuous production, works in tandem with advanced control systems, each optimized for peak performance in every process. Just load the machine, set it up and wait for your sintered materials.

Modular Flexibility

U-FAST MASS is uniquely suited for large-scale operations. Its ability to handle high pressure and maintain consistent vacuum levels throughout the whole process makes it invaluable in industrial settings. The sintering systems of U-FAST MASS are designed for adaptability, allowing adjustments in sintering parameters to cater to a variety of materials and production demands. This modular flexibility enables the machine to be tailored to various production scales and processes.

MASS for Energy Efficiency

When the material is processed in our continuous sintering machine through the powder passes high current pulses. It results in a very high heating rate of the material being sintered. It’s much more economical compared to heating the whole chamber. It also allows us to sinter the material in a very short time.

Redefining Manufacturing with Advanced Data Management

The advanced data management capabilities of U-FAST MASS continuous sintering machine allows you to see real time graphs and automatically creates data sheet after the process. The system diligently records and analyses a multitude of parameters, offering critical insights for making adjustments. It also make a post-process data analyse much easier. This high level of data management is crucial for maintaining the exemplary standards expected from top-tier sintering systems.

U-FAST MASS as a Beacon in scaling SPS technology up

U-FAST MASS stands at the forefront of sintering technology, particularly as an automatic sintering machine ideal for large-scale production. We believe it’s an unparalleled choice for industries seeking the utmost in efficiency, precision, and scalability. U-FAST MASS not only continues to push the boundaries in the world of SPS systems but also heralds a new era in manufacturing, marked by advanced technology and innovative solution.

U-FAST MASS is equipped with a proprietary high-efficiency energy-saving power supply that generates precise DC pulses with predefined parameters. It has a converter module and a rectifier that are mounted in a way that minimizes energy losses and eliminates unnecessary switching losses. This allows you to achieve higher heating rates with the same power output compared to other solutions.

U-FAST MASS is equipped with a proprietary high-efficiency energy-saving power supply that generates precise DC pulses with predefined parameters. It has a converter module and a rectifier that are mounted in a way that minimizes energy losses and eliminates unnecessary switching losses. This allows you to achieve higher heating rates with the same power output compared to other solutions.

The primary side power supply capacity is also reduced, making it more economical.

U-FAST MASS has a flexible modular structure that can be retrofitted to tunnel-type continuous furnaces with degassing chamber, sintering chamber, and cooling chamber. You can also add various material handling automation equipment, such as loading/unloading conveyor lanes and workpiece removal equipment, to enhance your productivity.

U-FAST MASS has a flexible modular structure that can be retrofitted to tunnel-type continuous furnaces with degassing chamber, sintering chamber, and cooling chamber. You can also add various material handling automation equipment, such as loading/unloading conveyor lanes and workpiece removal equipment, to enhance your productivity.

U-FAST MASS has an accurate process control system based on a Siemens PLC and software that provides full functionality. The main screen displays all the essential information and allows easy control of the process. The system measures and records various parameters, such as electrical current, voltage, temperature, pressure, Z-axis position, vacuum level, and others specified by the process.

U-FAST MASS has a short cycle time that makes it superior to conventional methods such as hot pressing, HIP, and normal pressure sintering. U-FAST MASS combines a state-of-the-art power source with stamps made from dedicated materials and a housing that reduces energy transmission losses and processing time. This results in the most precise DC heating system available in FAST/SPS technology. Accurate energy delivery is critical in applications where limited material grain growth is the most important parameter. U-FAST MASS can speed up your production process significantly and deliver high-quality materials in a short time.

U-FAST MASS has a short cycle time that makes it superior to conventional methods such as hot pressing, HIP, and normal pressure sintering. U-FAST MASS combines a state-of-the-art power source with stamps made from dedicated materials and a housing that reduces energy transmission losses and processing time. This results in the most precise DC heating system available in FAST/SPS technology. Accurate energy delivery is critical in applications where limited material grain growth is the most important parameter. U-FAST MASS can speed up your production process significantly and deliver high-quality materials in a short time.

Download GeniCore Device Catalog

Send download link to: