GeniCore U-FAST device thanks to its modular design allows to upgrade the device within the project progress which means the GC 85-HV model can be obtained even if initially the GC 35 model was acquired.

GeniCore U-FAST device thanks to its modular design allows to upgrade the device within the project progress which means the GC 85-HV model can be obtained even if initially the GC 35 model was acquired.

The GeniCore U-FAST GC model is a perfect fit for R&D scale and small batch production needs. It is designed for tech enterprises with R&D departments and manufacturing businesses that are keen on developing and experimenting with new materials. These materials can then be scaled up to larger diameters using the U-FAST MASS and U-FAST Hybrid devices for commercial scale applications.

* Max Current – The final value of the current is related to the value of the on-site connection voltage , so it can vary accordingly.

* Max Current – The final value of the current is related to the value of the on-site connection voltage , so it can vary accordingly.

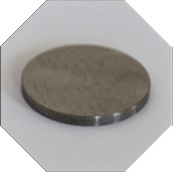

Manufacturing process

Graphite mold inside U-FAST vacuum chamber

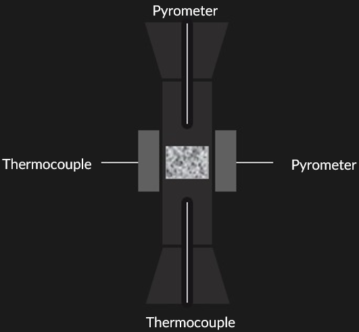

Temperature measurement

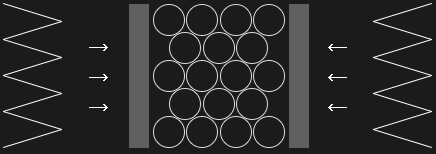

Conventional Method

- Heating by radiation

- Low heating factor

- Temperature gradient in sintered materials

- Time-consuming and energy-consuming processes

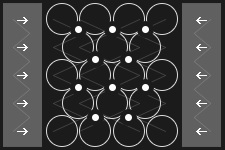

U-FAST technology

- Heating using Joule heating

- Fast, economical processes (30 min)

- Low energy consumption

- Lower sintering temperature

- Limited grain growth

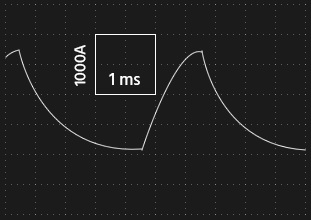

Pulse duration below 1 ms

Pulse duration, which lasts even less than 1ms, gives the advantage of our U-FAST sintering system over SPS devices from other machines available on the market. Current pulses are shown using an oscilloscope, demonstrating the efficiency of this machine within the vacuum chamber. Additionally, U-FAST technology offers a more environmentally friendly and sustainable approach to material production, reducing the carbon footprint and waste generated during the manufacturing process.

Furthermore, the U-FAST system provides a platform for researchers and engineers to explore a wide range of materials and their applications, fostering collaboration and innovation in various fields such as automotive, energy, and defence. By leveraging the benefits of SPS, U-FAST enables the creation of materials with exceptional properties and performance, opening up new opportunities for breakthroughs in material science and engineering.

Download GeniCore Device Catalog

Send download link to: