Introduction to Spark Plasma Sintering technology

Spark plasma, is a pulsed direct current used in the Spark Plasma Sintering (SPS) process. This innovative method, also known as spark plasma technology or field assisted sintering technology (FAST), offers numerous advantages in sintering materials, particularly ceramics. The spark plasma sintering process has gained considerable attention in recent years due to its potential to revolutionize the field of powder metallurgy and material processing.

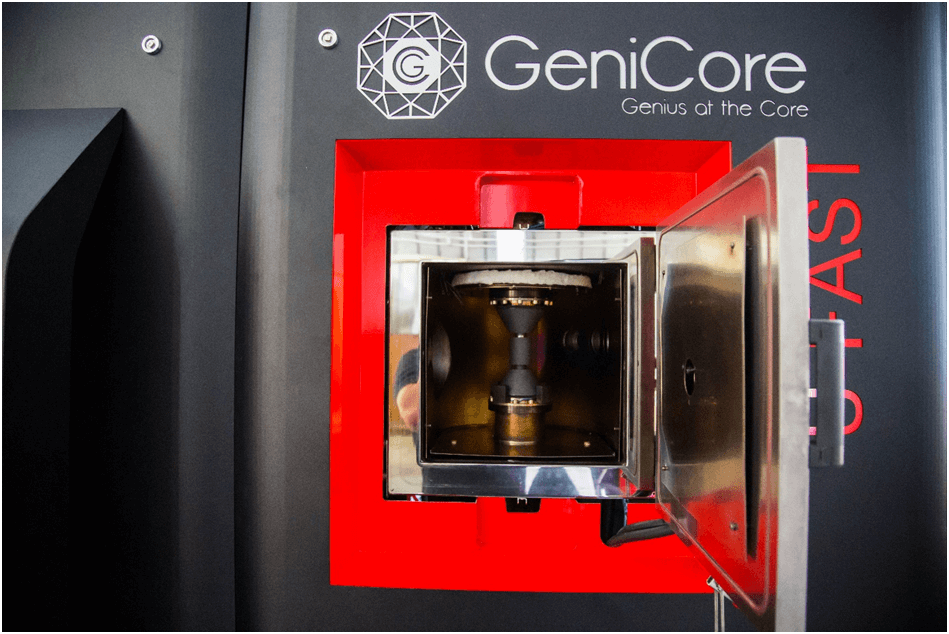

View of vacuum chamber with graphite set of SPS device

Advantages of Spark Plasma Sintering

The conventional powder consolidation process, known as hot pressing, involves heating a powder or pre-concentrated powder at a high temperature (typically 0.7 – 0.8 melting point in K), while simultaneously pressing it. The heating of the consolidated powder is usually carried out by heat transfer from the heating elements by radiation, convection and/or thermal conduction. However, hot pressing has several disadvantages such as high temperature, long process time and low heating efficiency of the consolidated powder. Furthermore, the high temperature and long consolidation process time are unfavorable for obtaining materials with specific properties such as materials with nanocrystalline microstructure.

More efficient and effective technique for consolidating powders is Spark Plasma Sintering in which the heating is carried out directly by an electric current flowing through the powder to be consolidated. In particular, techniques like U-FAST (Upgraded-Field Assisted Sintering Technique) in which short pulses of current are used to heat the powder to be consolidated meet this condition. In these technique, as in hot pressing, the consolidated powder is simultaneously pressed and heated with Joule heat. This method provides several benefits compared to conventional sintering techniques. Some advantages of the field assisted sintering technology (FAST) include:

- Rapid heating rates: The direct flow of current through (direct heating – conduction) the powder being sintered allows for significantly faster heating rates compared to traditional methods (indirect heating – radiation/convection), leading to reduced processing times.

- Reduced sintering temperatures: The localized heating generated by the spark plasma enables sintering at lower temperatures, which can be advantageous for materials sensitive to high temperatures or prone to grain growth.

- Shorter processing times: The combination of rapid heating rates and reduced sintering temperatures leads to shorter overall processing times, increasing production efficiency.

- Enhanced control over microstructures: The SPS technology allows for better control over the heating and cooling rates, leading to the formation of materials with tailored properties and microstructures.

- Energy efficiency: The localized heating effect in the FAST process reduces the overall energy consumption compared to traditional sintering techniques, resulting in a more environmentally friendly and cost-effective production process.

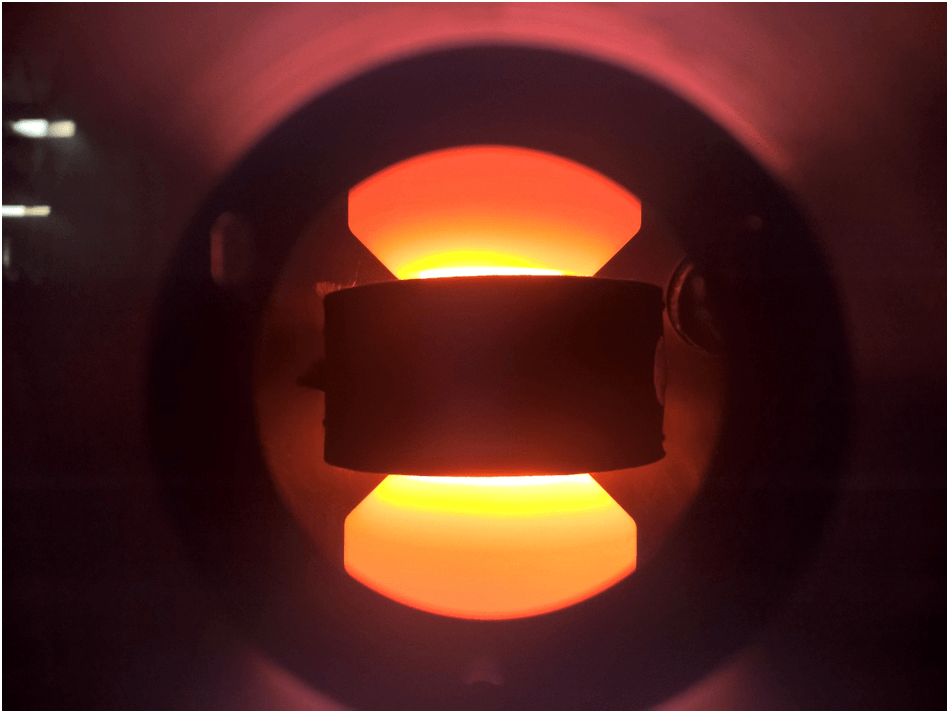

View of the graphite set during the Spark Plasma Sintering process

Principle of Spark Plasma Sintering

The underlying principle of spark plasma sintering is the application of a pulsed direct current through a conductive die and powder material during the sintering process. This generates localized heating, promoting efficient particle bonding and densification. The SPS technology allows for better control over the heating and cooling rates, which contributes to the formation of materials with tailored properties. The use of direct heating of the powder with pulses of electric current increases the rate of consolidation and also accelerates the consolidation process by activating one or more simultaneously occurring mechanisms such as the removal of oxides from the surface of the powders, an increase in the rate of diffusion processes due to the presence of an electric field (electromigration) and the rate of plastic deformation (electroplasticity).

Applications of Spark Plasma Sintering

The versatility of the FAST process makes it suitable for a wide range of applications, including:

- Ceramics: Spark plasma sintered ceramics exhibit enhanced mechanical properties due to their fine-grained microstructures and near-full density. This makes them ideal for use in wear-resistant components, cutting tools, and structural components.

- Metals: this technology can be employed to sinter metal powders, producing components with high strength and improved fatigue resistance, which are essential in industries such as aerospace and automotive.

- Metal Matrix Composites: The FAST process is well-suited for producing metal matrix composites with tailored properties, enabling the development of materials with enhanced mechanical and thermal performance.

- Nanostructured Materials: The rapid heating rates and precise control over the sintering process make SPS systems an excellent choice for producing nanostructured materials, which have unique properties and a wide range of potential applications.

- Advanced Functional Materials: The FAST process is also applicable to the fabrication of advanced functional materials, such as thermoelectric materials, superconductors, and energy storage materials, providing new opportunities for technological advancements.

Conclusion

U-FAST offers significant advantages in sintering materials, especially ceramics. By utilizing the SPS method and SPS systems, researchers and manufacturers can develop advanced materials with tailored properties, expanding the potential applications for these materials in various industries. As the demand for high-performance materials continues to grow, the spark plasma sintering process is expected to play an increasingly important role in the development and production of next-generation materials.