PPC Technology

This equipment is intended for the application to the sintered set of high and narrow current impulses repeated at a high frequency, whilst ensuring a long duration of the high-current electronic key in the capacitors’ battery discharge circuit. One of the factors behind the usage of the high-current electronic keys is the formation of rectangular impulses with the duration of several hundred microseconds and adjustable amperage already for several kA. The possibility of forming current impulses cannot be reached using other well-known semiconductor connectors or mechanical switches, which use oscillatory discharge of the battery – the amplitude of each successive half is smaller and cannot be controlled/monitored, so the value of the supplied energy is variable.

One of the GeniCore solutions used in the PPC device:

- Rectangular impulses

- Equal amplitude

- The ability to control by the shape of the impulse through signal controlling the work of the electronic key – battery discharge – fading oscillating course vs. rectangular

- Rectangular course – impossible to obtain with other mechanical and semiconductor switches

Sintering unit includes the following main modules:

- Vacuum Chamber with pumping system and press frame

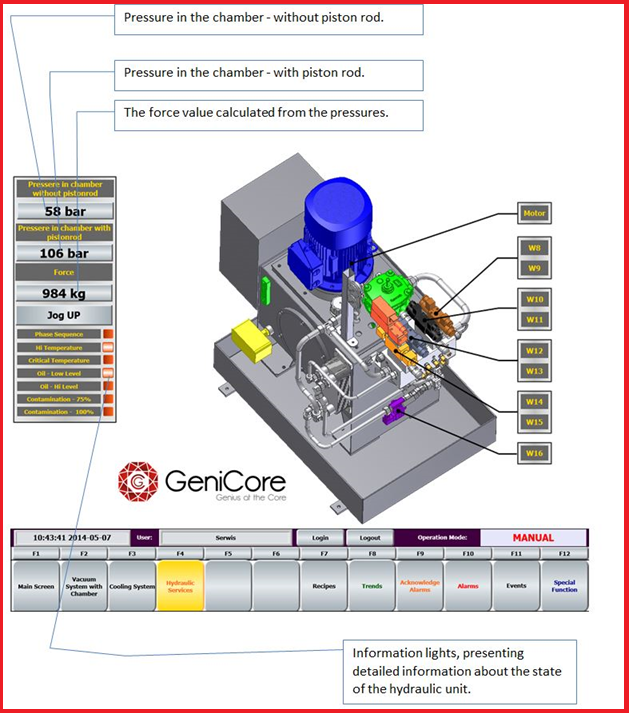

- Hydraulic Unit

- HV Power Supply

- HV Capacitor Bank

- HV Electronic Key

Vacuum Chamber is equipped with vacuum-voltage glands together with electrically insulated slidable punches and electric terminals

Pulse Plasma Compaction method is a universal and efficient way of powder consolidation. Its universality provides a possibility to consolidate pure metal powders, metal alloys and ceramic and metal composites. Sintering efficiency results from hot pressing, in which the powder is heated up using short high current impulses.

During the PPC process, electrical energy stored in the battery of capacitors is dissipated in a closed circuit of capacitors /consolidated powder / stamps using electronic switch. Capacitor bank is adapted to pulse operation at the voltage of 2000 V and big rates of current rise. The main advantages of this method are short sintering time and low pressing load.

Control hardware of PPC devices consist of:

- PLC controller in which the control algorithm for Sintering Machine is implemented

- Touchscreen of HMI system, which enables current operation of the device

- PC for preparing recipes

- IP camera that records production process taking place inside the chamber and archiving the data on the PC

- HMI workstation is an industrial computer operated via 17″ touchscreen. It is a built-in control cabinet hanged on the boom

Communication between computers and PLC takes place using Modbus TCP/IP network.