ballistic ceramic plates of various geometries

and devices to manufacture those

We ensure:

- Superior quality and more economically efficient solutions

- Reduced electricity consumption and higher efficiency

- Materials and devices: ballistic ceramic plates of various geometries.

- We can accomplish this quickly and in large quantities.

Lead to operational cost savings around 30% compared to HP technologies

ADVANCED CERAMIC MATERIALS FOR ARMOR APPLICATIONS

- Ceramic tiles available in various shapes and sizes

- Compatible for use in finished armor systems

- Exceptional hardness for advanced threats

- Reduced weight for improved mobility

- Enhanced performance benefits

- Density close to theoretical value

- Controlled uniformity of microstructures

- High-purity materials ensuring reliability

Some of the materials we can produce:

| Aluminium Nitride | Boron Carbide | Titanium Diboride | Alumina-Zirconia Composite | Silicon Carbide |

| AIN | B4C | TiB2 | ZrO2 | SiC |

Comparison of sintering parameters based on SiC material

| METHOD | SINTERING TEMPERATURE [°C] |

DWELL TIME OF PRCESS [MIN] |

COOLING TIME |

MAX. GRAIN SIZE [μM] |

| U-FAST TECHNOLOGY |

1950 | 60 | 15 MIN | 6 |

| CONVENTIONAL SINTERING |

2150 | 270 + COOLING |

FEW HOURS | 60 |

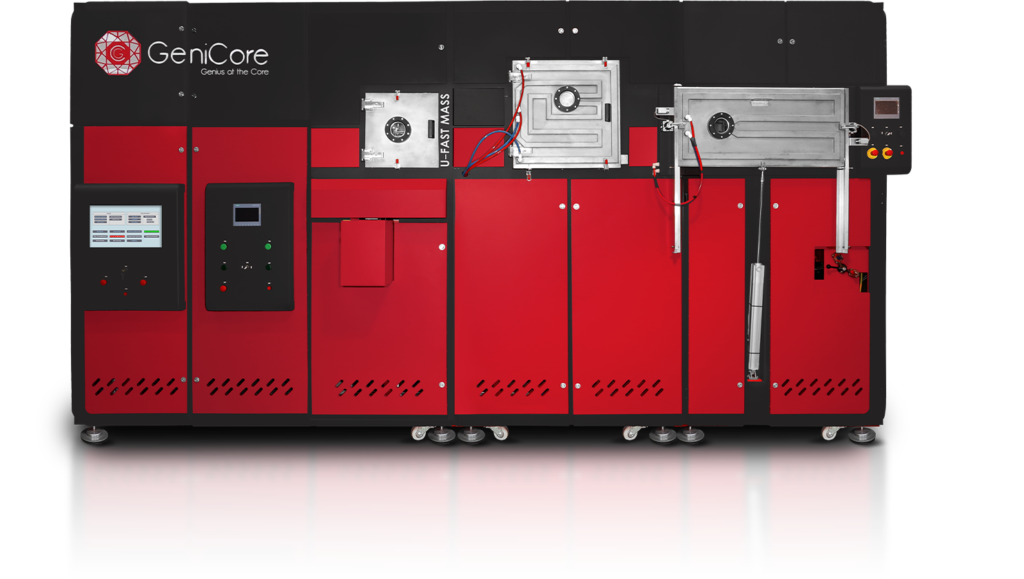

U-FAST TECHNOLOGY

Represents of spark plasma sintering that sets new standards in the sintering process. Our innovation is based on advanced technology that generates current pulses with a duration shorter than 1 ms, enabling sintering of materials with minimal or zero grain growth.

Why Our Technology Stands Out:

- Heat generated inside the material and matrix

- Cost-effective manufacturing

- One-stage process and near net shape production

- Short sintering process time

- Reduction in sintering temperature