Powder Metallurgy Techniques and Production Methods

Key techniques in powder metallurgy include mechanical alloying, gas atomization, water atomization, electrolysis, and chemical reduction. These methods produce high-quality metal powder for various applications, such as aerospace turbine engine components and automotive parts. Among these techniques, gas atomization is the most widely used method for producing powdered metals due to its versatility in generating diverse particle sizes and high-quality powders. In this process, a molten metal stream is atomized by a high-pressure gas stream, forming fine powder particles. This technique is crucial for creating lightweight components in the automotive and aerospace industries, where fuel efficiency and weight reduction are essential.

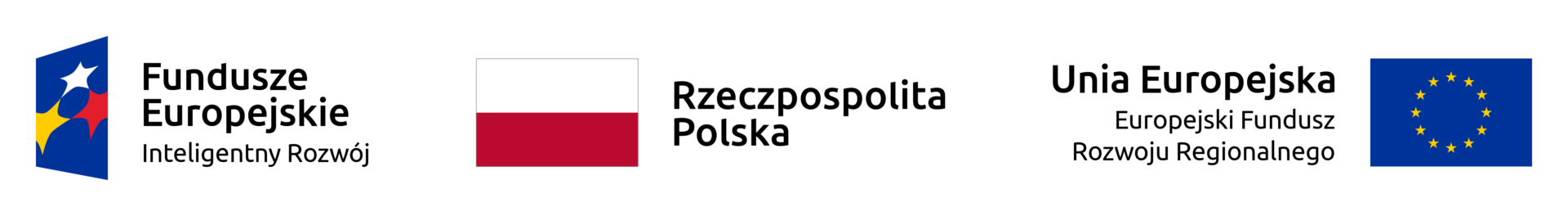

PZ36 SEM image of WC powder

Materials and Processes in Powder Metallurgy

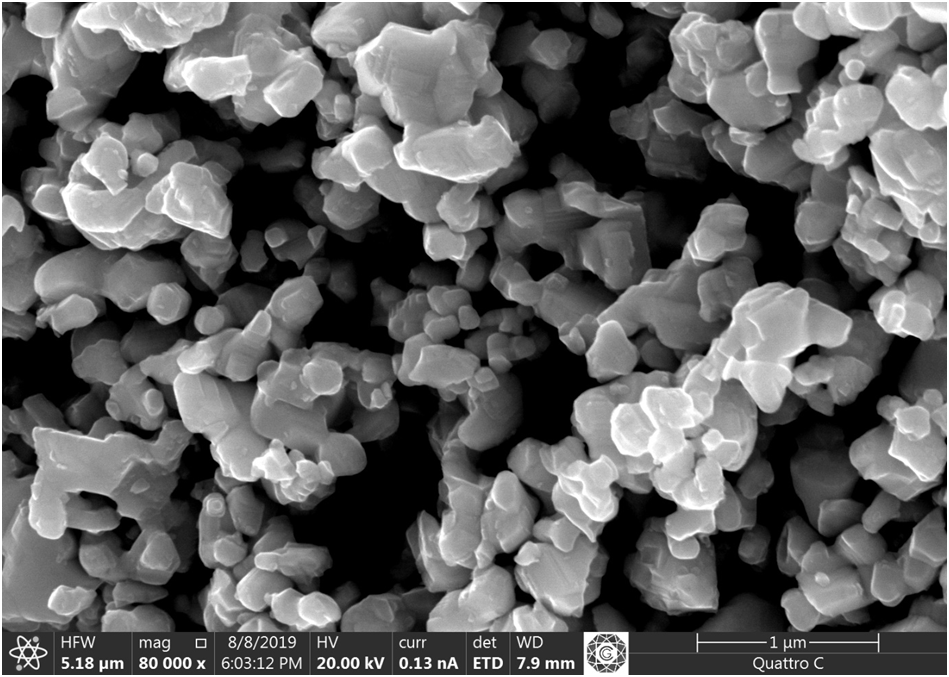

WCCo powder placed in graphite die

A wide range of materials can be used for powder metallurgy, including ferrous and non-ferrous metals, ceramics, and polymers. The most common materials include iron and steel, aluminum, copper, nickel, and titanium. These materials are chosen based on their properties and the desired characteristics of the final product, such as strength, corrosion resistance, and wear resistance. For example, titanium is often used in aerospace and medical applications due to its high strength-to-weight ratio and biocompatibility.

The powder metallurgy process involves several steps: powder production, blending and mixing, compaction, and sintering. This process is widely used in various industries to create components with unique properties and intricate geometries that would be difficult or impossible to achieve through traditional manufacturing methods. For instance, the medical industry utilizes powder metallurgy to produce customized implants, while the electronics industry benefits from the production of highly compact and thermally conductive components.

Advanced Techniques in Powder Metallurgy

Sponge Iron Process

The sponge iron process is a method used to produce high-purity iron powder, which involves reducing iron oxide with hydrogen or carbon monoxide. This method results in a porous, sponge-like structure that can be further processed for various powder metallurgy applications, such as the production of soft magnetic components for electric motors and transformers.

Metal Additive Manufacturing

Metal Additive Manufacturing is a technique that uses a layer-by-layer approach to build 3D objects. This process offers numerous advantages, such as design flexibility, reduced material waste, and the ability to produce complex geometries. Industries such as aerospace and automotive have adopted this method to create highly optimized, lightweight components that improve fuel efficiency and overall performance.

Metal Injection Moulding

MIM is another advanced powder metallurgy technique that involves injecting a mixture of metal powder and a thermoplastic binder into a mold. The part is then heated to remove the binder and sintered to create a fully dense component. MIM is suitable for producing intricate shapes and components with tight tolerances. This technique is widely used in the production of medical devices, such as surgical instruments and dental implants, due to its precision and ability.

Sinter Powder Metallurgy

Sintering is a crucial step in the powder metallurgy process. During sintering, the compacted part is heated to a temperature below its melting point, allowing the particles to bond and form a solid part. This process helps achieve the desired mechanical properties and dimensional stability of the final product.

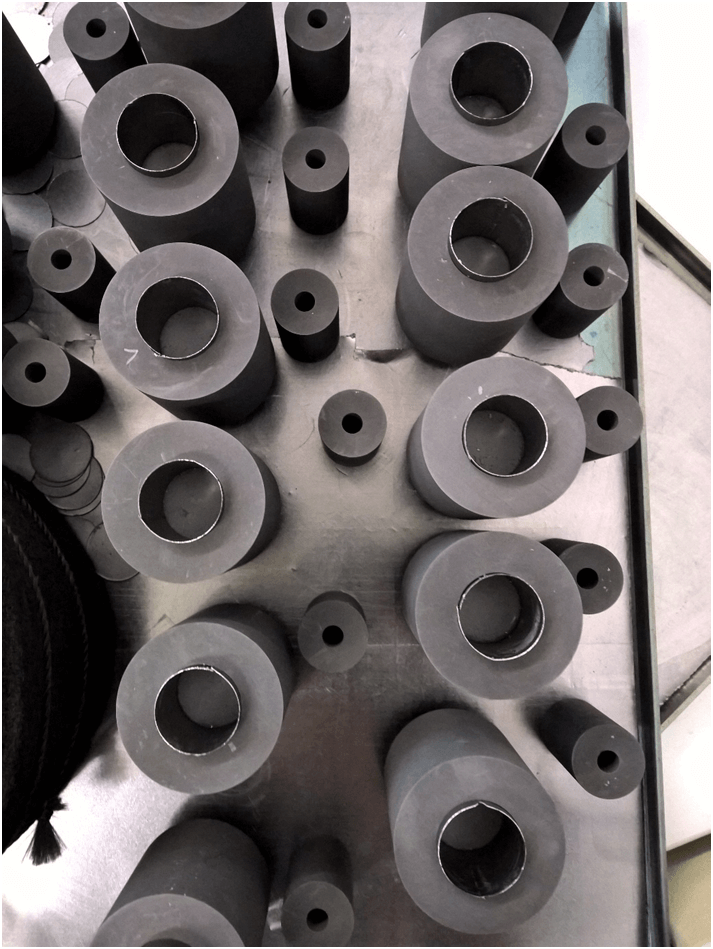

View of graphite set with WCCo powder being sintered during SPS process.