Key Capabilities

- Ultra-fast densification: custom-shaped pulses < 1 ms prevent grain growth.

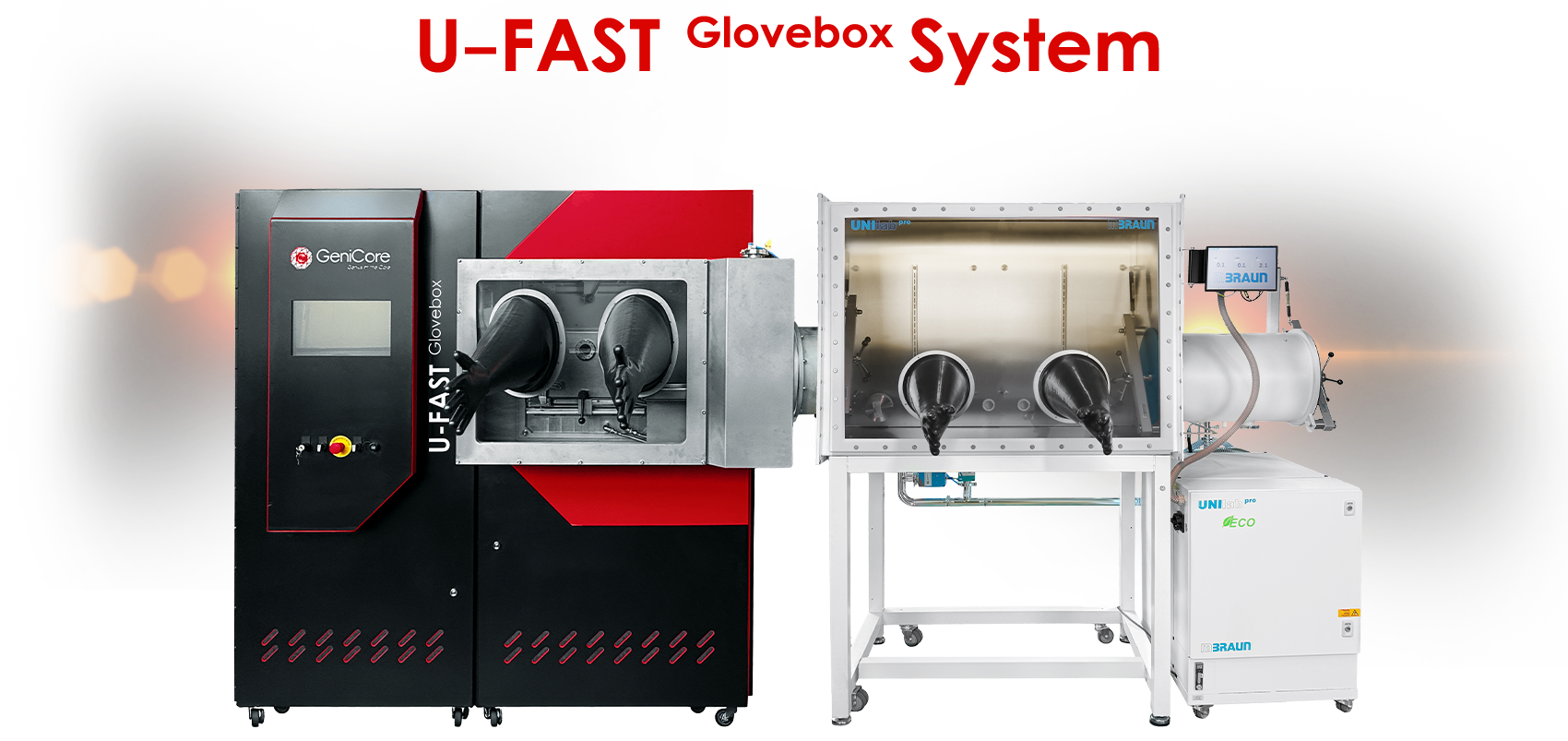

- Controlled inert atmosphere: MBRAUN glovebox ensures minimal contamination and superior gas purity control.

- Modular upgrade path: from compact GC55 to high-capacity GC85-HV, without replacing the base system.

- Independent or integrated operation: glovebox and sintering unit can operate independently or as a combined solution.

- Process monitoring: Siemens PLC with live data logging and analysis.

Collaboration with MBRAUN

The glovebox system is delivered in strategic partnership with MBRAUN, ensuring:

- Minimal contamination and superior inert gas control.

- Ergonomic and modular chamber design.

- Optional purification and automation upgrades.

Designed for Advanced Materials

- R&D and low-volume production of oxygen- and moisture-sensitive materials.

- Applications in electronics, energy, aerospace, and tooling.

- Suitable for Bulk Metallic Glasses (BMGs), High-Entropy Alloys (HEAs), transparent ceramics, thermoelectrics, and nanomaterials.

Why U-FAST in a Glovebox?

- Future-proof for next-gen materials (HEA, BMG, transparent ceramics).

- Scalable Processes: transfer processes from GC systems to U-FAST MASS or U-FAST Hybrid.

- Compact footprint: ideal for laboratories with limited space.

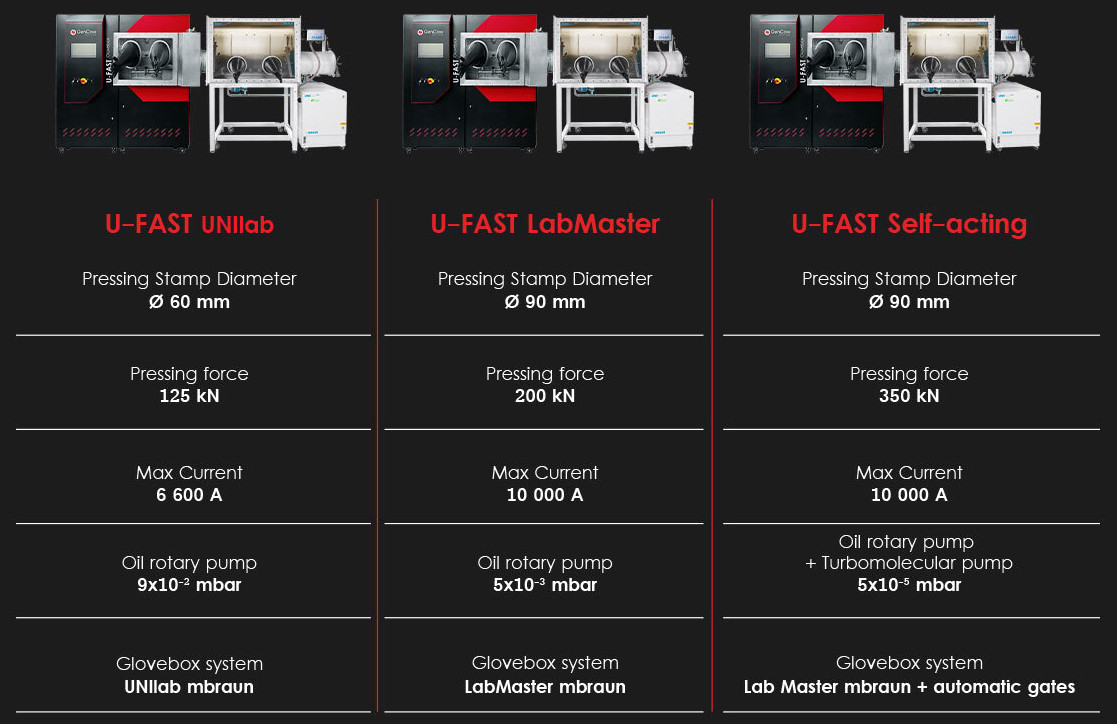

System Configurations

Frequently Asked Questions

What materials benefit from SPS in a glovebox?

Can I upgrade from GC55 to GC85-HV without replacing the base?

How is process quality controlled?

What materials benefit most from an inert atmosphere during SPS?

Can the system be upgraded to handle larger samples in the future?

How does the system ensure process repeatability and quality?

How does U-FAST technology differ from conventional Spark Plasma Sintering (SPS)?

What is the main advantage of an integrated SPS-glovebox system over two separate units?

Download GeniCore Device Catalog

Send download link to: