In order to achieve the desired cutting performance for diamond tools, special attention should be paid to the requirements set in terms of the matrix. Excessive wear level of the matrix shall lead to prematurely pulling the diamond particles, while too low wear leads to rounded sharp edges of the diamond. In addition, the matrix has to be characterized by high strength at high temperatures and resistance to dynamic load in order to resist the high temperature and vibration occurring in the cutting process.

A new group of sinter tools for processing of construction materials are super-hard composite materials based on diamond and cemented carbide matrix. The high hardness of the matrix made from cemented carbide can improve the resistance to abrasive wear of these tools and the strong bonding of diamond particles with the matrix.

Specific feature appearing during PPC process make a possibility to fabricate a new, created by GeniCore, material as is a DEC. The DEC (Diamond Enhanced Cemented Carbide) can be produced during the thermodynamic impermanence of the diamond, which is what renders this process technologically competitive when compared with traditional sintering methods (which prohibit diamond sintering due to the graphitization process) and financially competitive when confronted with HPTP diamond sintering methods.

Diamond Enhanced Cemented Carbide Properties

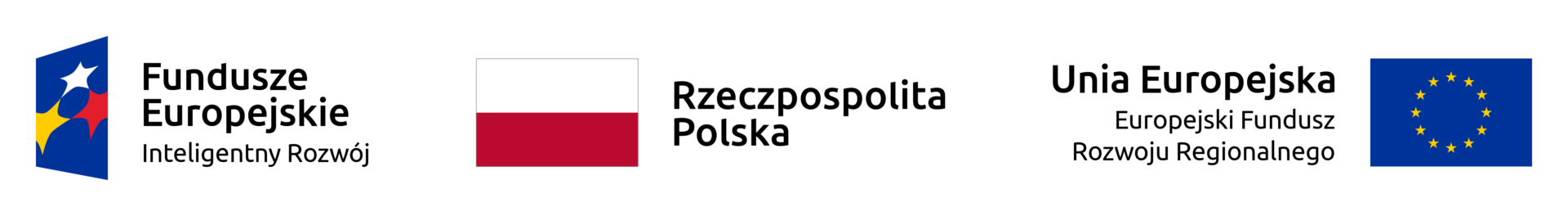

Material’s phases:

Phases of the WC-Co matrix: orange – WC, purple – Co

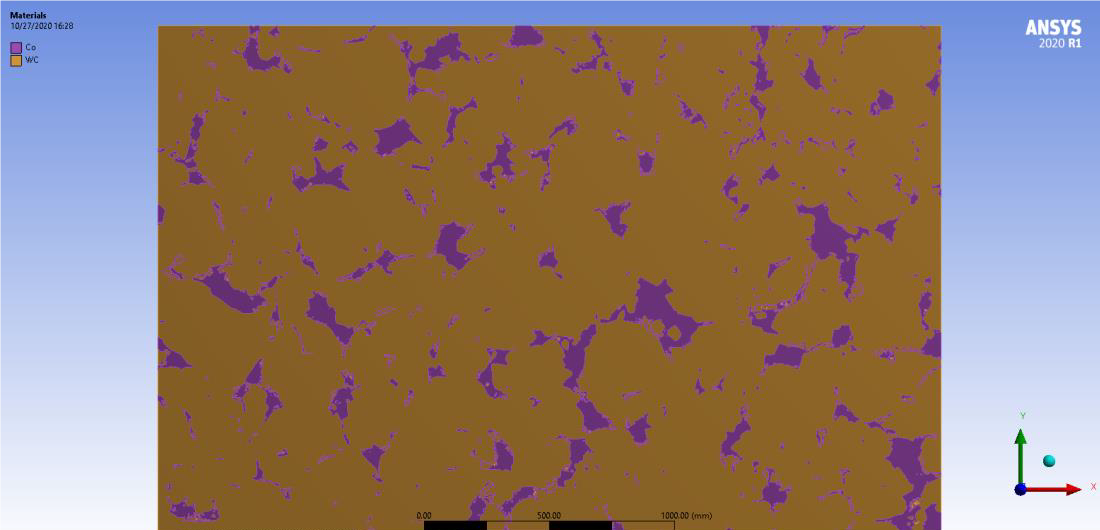

Tensile simulation:

Internal material stresses in the WC-Co matrix under 344.5 MPa external tensile stress

Using extracted model’s strain Young’s Modulus have been calculated. Obtained value of Young’s modulus for WC-Co matrix is E=493.39 GPa.

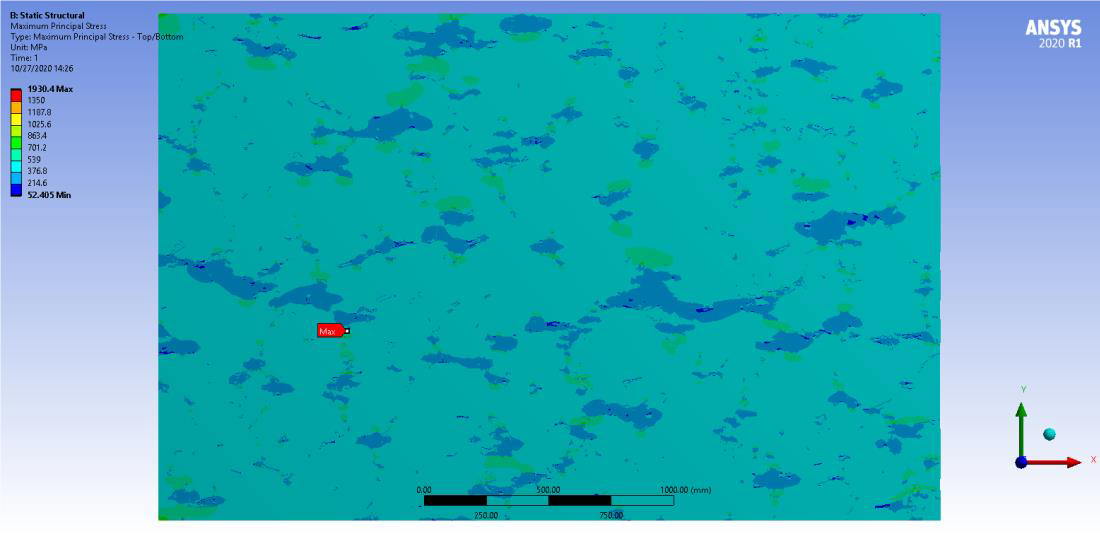

Thermal expansion:

Stresses caused by thermal expansion of the WC-Co model

Heating the material’s model from 22℃ to 422℃ (ΔT=400℃) thermal expansion was simulated

Extracting strain from the solver using temperature difference (ΔT=400℃) thermal expansion was calculated. Simulated thermal expansion value for WC-Co matrix is α=6.13*10-6 [1/K].

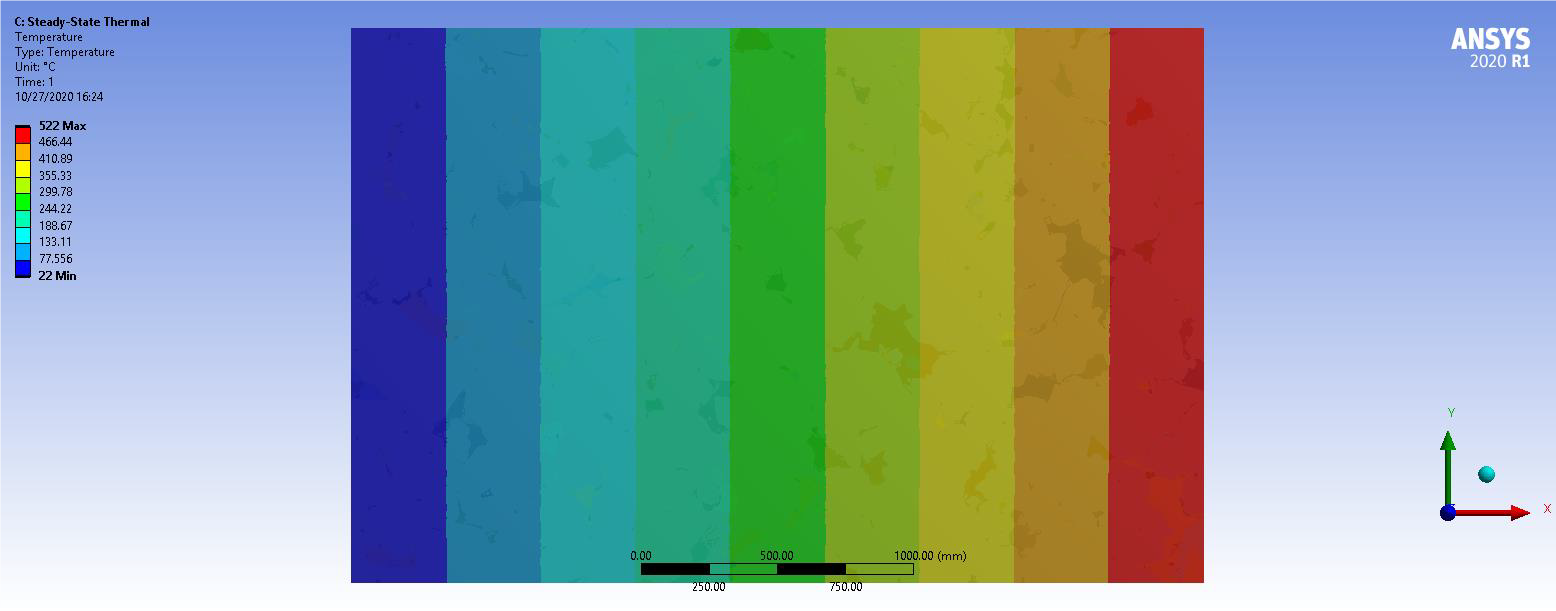

Thermal conductivity:

Temperature distribution over WC-Co microstructure model