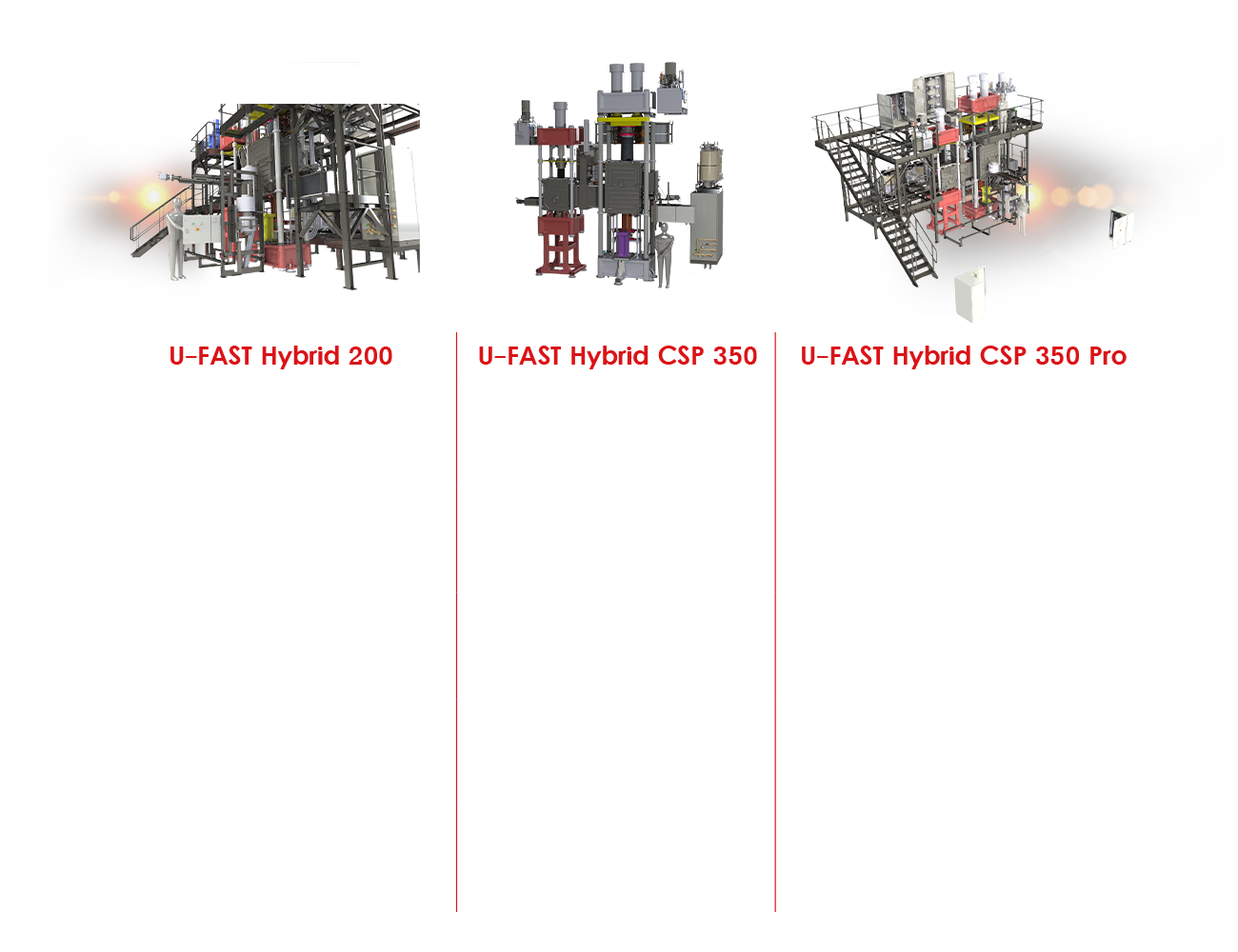

WITH U-FAST HYBRID YOU CAN GO BIG

SINTER MATERIAL UP TO ⌀ 200 [mm]

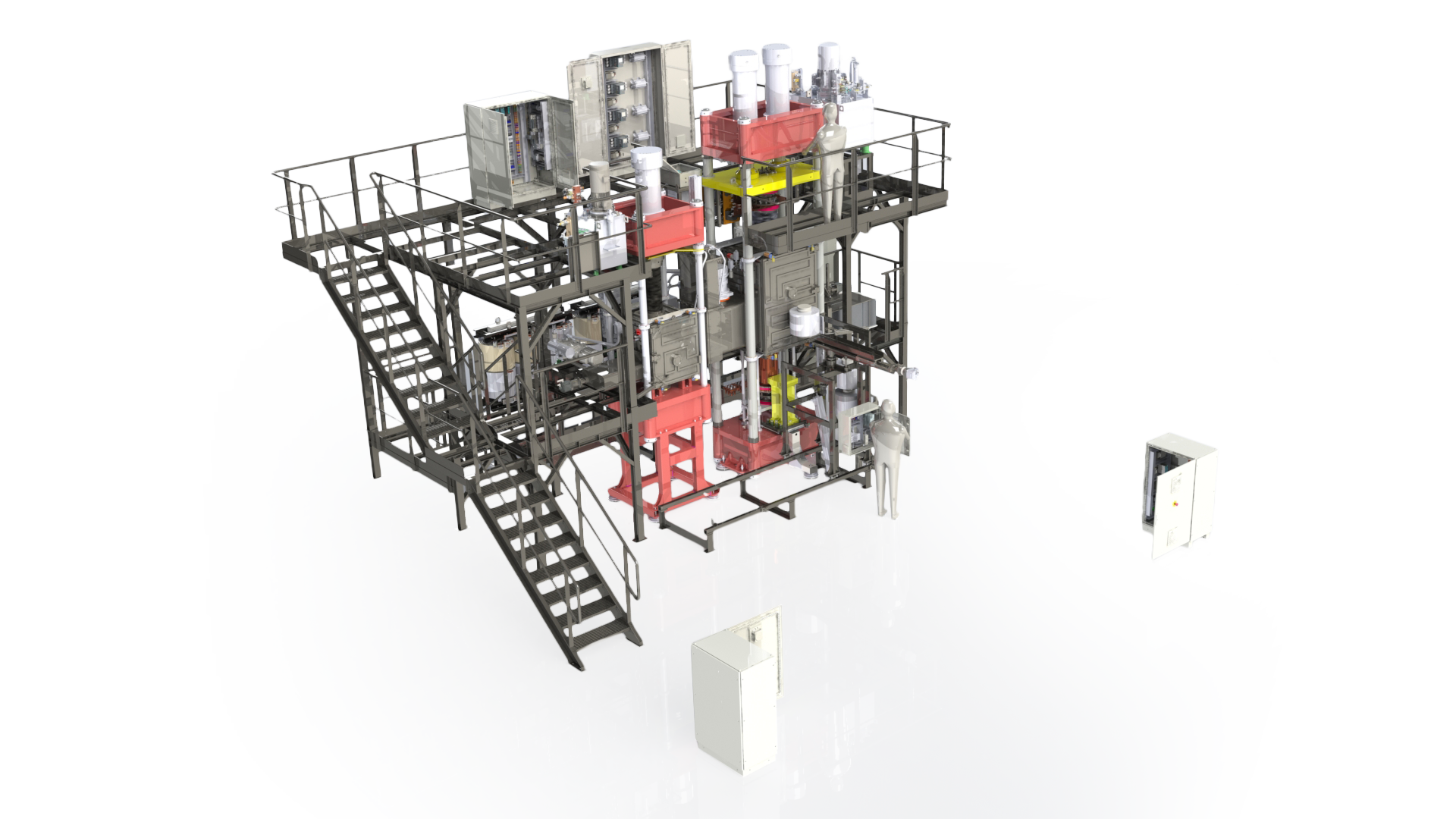

Available models:

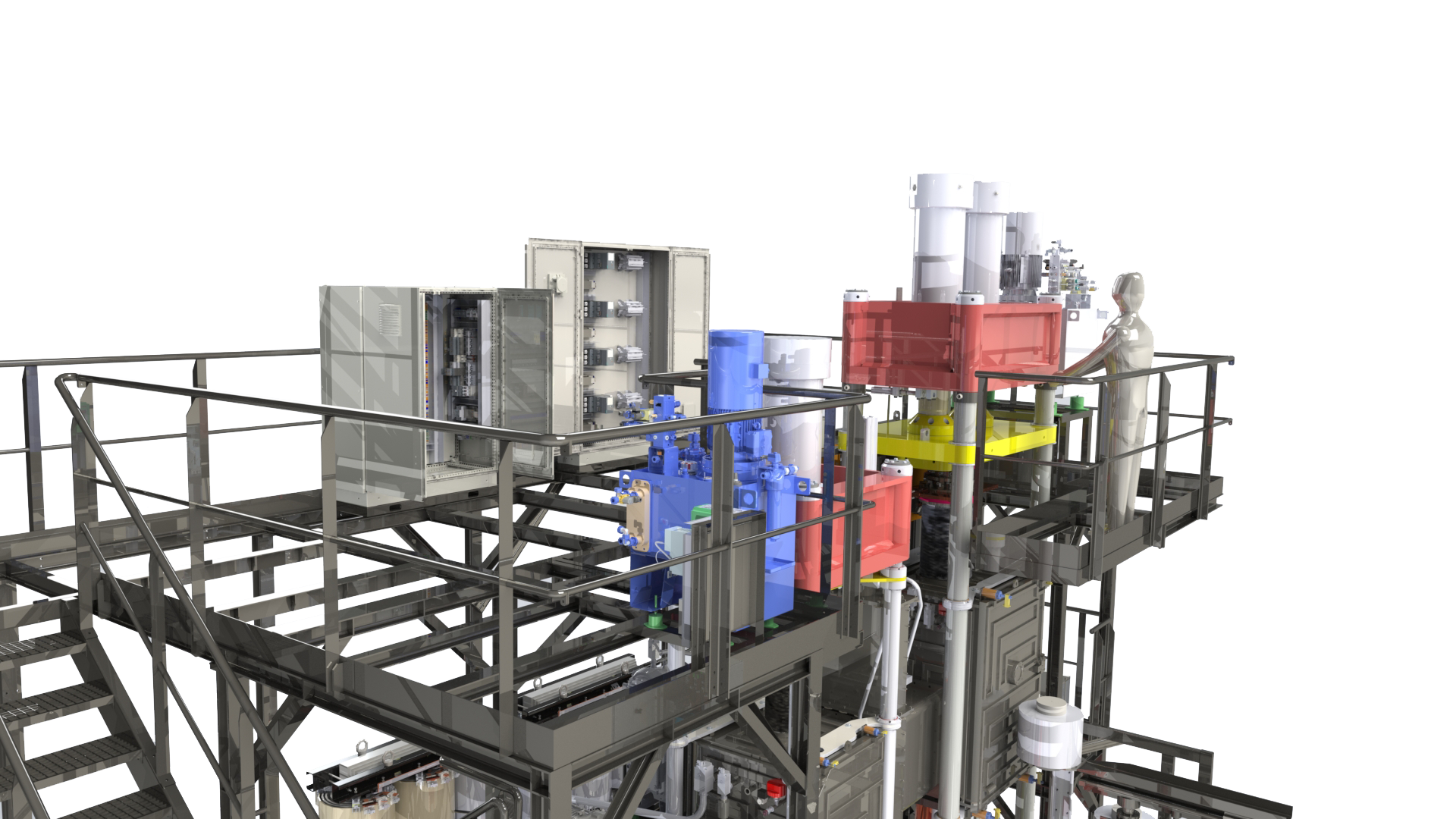

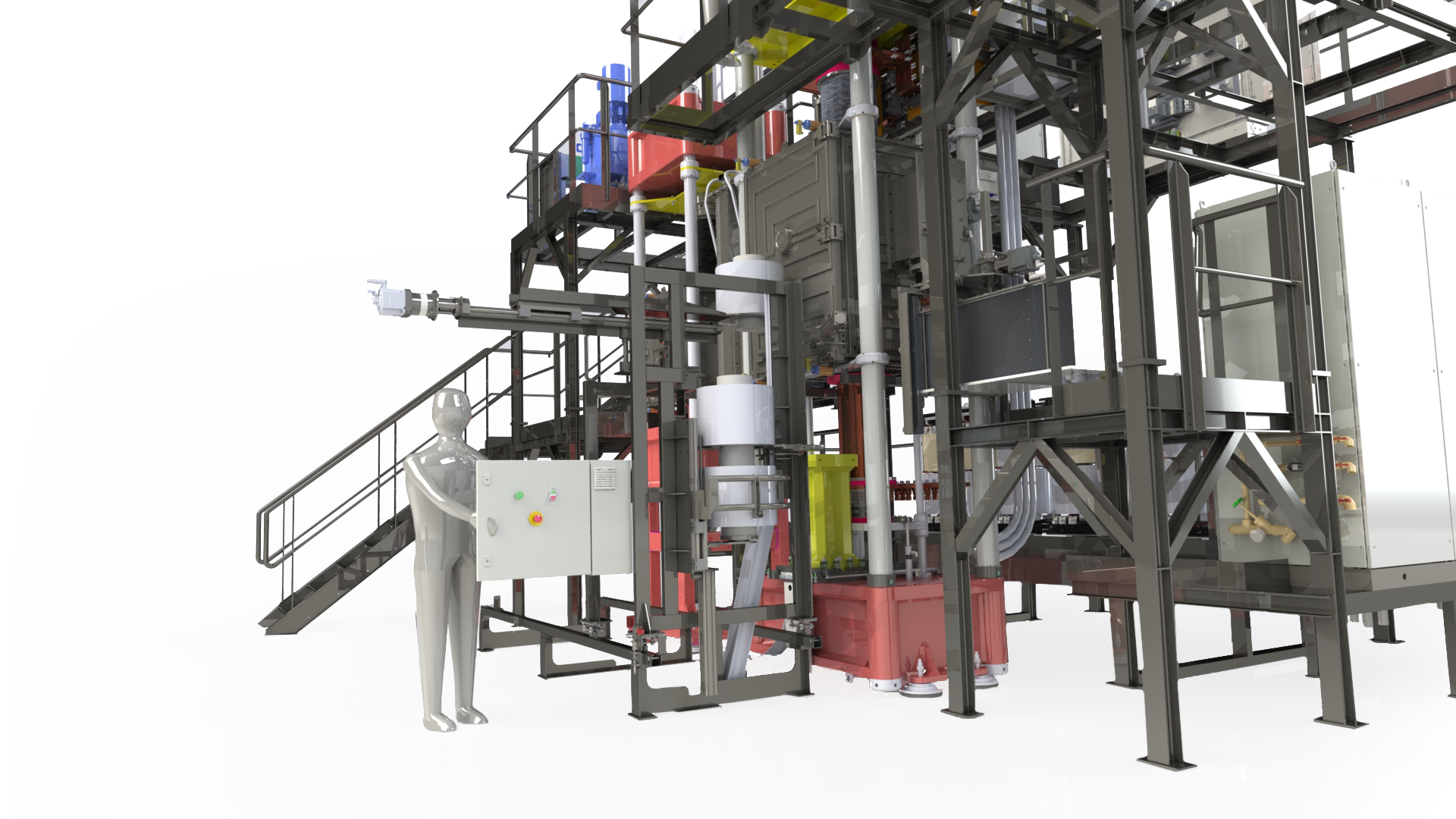

Double chambers system in the hybrid sintering machine

The cooling phase is critical, especially for sintering diameters in the range of hundreds of millimetres, due to the prolonged time needed for the sample to cool. As the sintering diameter increases, the cooling stage, at times, exceeds the duration of the sintering stage. Addressing this challenge, GeniCore incorporates a Continuous Sintering Process (CSP) with an extra vacuum chamber to enhance the manufacturing productivity.

The U-FAST Hybrid CSP model cools the graphite set using hydraulic press stamps that feature internal water channels for quick initial cooling. This process is seamlessly designed to transition to the next sintering cycle without delay, marking a significant development in sintering process technology.

Shortest pulses on the market

The U-FAST Hybrid’s power supply is tailored to deliver pulsed current, with adjustable parameters such as peak value (5–60kA), pulse duration, and pulse break, offering unmatched control over the sintering process.

This capability ensures that the machine can achieve the necessary power for optimal sintering temperatures. We also made sure to reduce current pulse rise time, including low inductance connections and specialized stamp construction, enhance the machine‘s performance.

The fully automated vacuum door was designed by GeniCore to provide easy access to the chamber and when combined with onsite automated loading system have great impact on device productivity.

Automated loading system

A fully automated vacuum door provides access to the sintering chamber, significantly boosting machine productivity alongside an onsite automated loading system. The machine‘s vacuum chambers are designed with minimal angles to simplify cleaning, accommodating mold sets up to ⌀200. This design consideration ensures maintenance ease and tooling and manufacturing flexibility, underscoring the machine‘s role in advancing manufacturing technologies.

Induction heating, as a secondary power source, guarantees uniform temperature distribution across the materials, essential for high-quality sintering. The machine’s AC generator, capable of delivering 350kW, maximizes efficiency. The induction coil, an easily exchangeable component, together in combination with the coil feedthrough design, ensures consistent, symmetrical heating. This approach effectively minimizes material shrinkage during the sintering process.

U-FAST Hybrid machine showcases GeniCore’s pivotal role in the evolution of sintering technology. By emphasizing innovative cooling strategies, combination heating sources, precise power management, and automation features, the U-FAST Hybrid is poised to significantly impact the manufacturing industries, reinforcing its status as a critical spark hybrid sintering machine in the advancement of sintering technology and the best-quality material produced.

We are confident that this machine holds versatile applications across various sectors including development of the PVD targets, development of advanced ballistic plates, brake pads, and aerospace.

Download GeniCore Device Catalog

Send download link to: